Engineering & Spares

CTC Milling cutter

CTC Cutters are manufactured from imported AISI M15 high speed steel. These cutters are available both in LH and RH forms. Cutters are available different angles as customers demand.

Optimum combination of microstructure ,grain size and hardness are ensured in heat treatment for durable performance.

On specific demand cutters are also made from AISI M-35 / M-42 / M-2 and other HSS grades of customer’s choice.

Hardness of TTI cutters is 66/68 HRC for M-15 and other grades of super-high speed steel.

64/66 HRC for M2 and other grades of conventional high speed steel.

CTC Chaser

We are a Supplier of CTC Chasers, made in compliance with International Standards. The tools are heat treated in microprocessor-based heat treatment furnaces to impart optimum hardness, toughness, and cutting power.

These are manufactured using high grade raw materials, which ensures the best performance and maximum durability. The high tensile strength of the tool ensures longer tool life.

These are available in different specifications to fulfill the different requirements of the customers. CTC Chasers help in achieving high-quality threading with close thread tolerances.

These are also used for producing accurate tooth form on fresh CTC Segments and facilitate in re-sharpening of CTC Rollers.

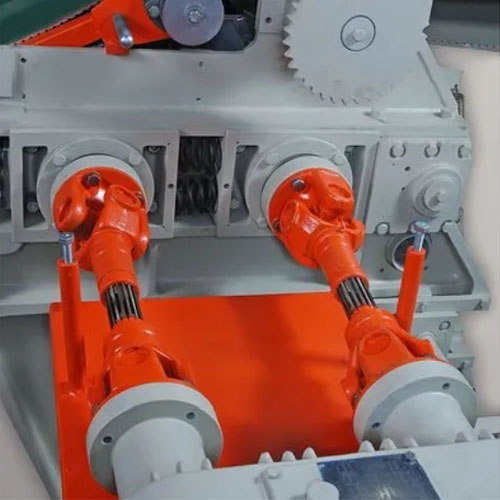

CTC bearing blocks

We is in the business of regular supply of all kinds of industrial bearings, earth mover bearings, double row spherical roller bearings, Taper Roller Bearings, Thrust Bearings, Unit Bearings, Needle Roller Bearings, Plummer Blocks, and sleeves CNC

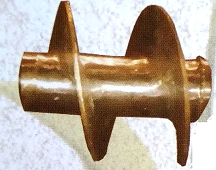

Rotorvan Spriral Part

Rotorvane is a maceration equipment, which is used as a pre-conditioner for withered leaf prior to processing in the main CTC Tea machine for black CTC tea manufacture. It has a positive effect on liquoring qualities.

Rotorvane consists of a cylindrical drum of a diameter of 200 cm (8″), 380 cm (15″) or 460 cm (18″), depending on the capacity. Inside the circumference of the drum, the resistors are fitted at appropriate distances.

Axial Flow Fan

We have been at the forefront of axial fan technology since the earliest days of its development, and we continue to lead the world in raising energy efficiency, improving reliability and reducing lifetime costs for our customers.

Many of our fans are serving in applications where durability and performance is key to continued operations. Our substantial installed base and long customer relationships bear witness to the high-quality finishing of our fans and excellence in engineering design.

This is carried through from bespoke fans for power and mining to standardised fans supporting ventilation in transport tunnels and air provision in light industrial settings.

Forged Segments

ESAL is a pioneer in making solid Stainless Steel Forged CTC Segments. Segments are being used by large number of Tea Planters and CTC Machine manufacturers as Original Equipment.These are known for offering excellent performance and long service life.

Segments have uniform fine grained selected prime stainless steel bars which are tested for excellent mechanical properties. Segments are a blend of latest technology and expertise and a product of proven efficiency. Every piece goes through stringent Quality Control methods to ensure cent percent reliability.

More and more Tea Planters are switching over to Segments as they are found to be of highest quality conforming to IS:8748/1978.

CTC Segment 8 “ to 13”

Manufactured from prime stainless steel bars.

2.100% authentic metallurgical standards conforming to ISS: 8748/1978.

Ultrasonically tested free from internal defects and high tensile strength ensures longer life.

Available in size 81/4″x2″, 81/2″x2″, 91/2×2″, and 13″x2″ , plain precision mechanised or milled and grooved.

Heater Spares

Air Heater is an improved form of the basic concept of hot air generating system. Ambient air enters into the air heater from the side top and being heated from the hot surfaces, it flows into the drying chamber being drawn by the drier’s hot air fan.

Flue gases are drawn by the Induced Drought Fan through the two vertical rows of tube banks on either sides of the furnace area and casting surfaces to the chimney.

CTC Spares