Esal Khari Green Leaf Sifter

Introduction

Manpower shortage is the new bane of the Tea Industry and the realist must realize that this is here to stay. Machine plucking to supplement hand plucking is creeping in and may eventually even replace hand plucking altogether. Compounded by bought leaf, the Tea Maker of today has the unenviable challenge of making decent tea with coarse leaf over which he has no control. This machine has been a huge success in factories which processes Bought Leaf OR Dual Leaf – own Garden Leaf & Bought Leaf.’

The ESAL KHARI SIFTER is the answer to his prayers! Not entirely a new concept as some factories have been using the balanced sifters to separate the stalks or kharis after reconditioning in the Rotorvane in various degree of success.

What Esal brings you is a machine specifically designed for this job. A small step in bringing Science to the Art of tea making!

The extracted Khari leaves are passed through a spill cut CTC machine. This process eliminates most of the Khari’s that converts into fibers. The need for such equipment was long felt in the industry and we took the initiative to develop this machine.

The Process

Tender, succulent leaf readily macerates in the Rotorvane/Pre-conditioner. Coarse leaf requires more severe treatment. Using medium pressure in the Rotorvane, the preconditioned leaf is fed to the Khari Sifter through a feed conveyor / spreader arrangement. The sifted fines are passed on to CTC machine for further processing and khari leaves are moved out using a slip conveyor to the secondary production line.

Reason why you will find the New Esal Khari Sifter useful

• Enhanced value of your primary Tea because of Superior Quality of Tea Produced.

• Saving on time, floor space and number of machines you would need for removing fibers in the Sorting room.

Machine Output

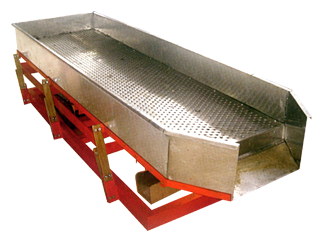

The Stainless Steel (304) tray is specially designed to give an output that can match the output desired for on-line processing and can easily sync with the production capacity of a Rotorvane and a 52″ CTC machine. It has been observed that between 2% to 3% Khari Leaves are extracted per hour which is fantastic.

Power

The newly designed counter weight in the drum pulley is provided so that the machine needs only 1/3 H.P. Power while in full speed with tea leaves. To overcome the initial starting torque a 1 H.P. motor is provided. The silent conveyor at the bottom of the tray runs on a 1 HP Grease sealed Geared Motor.

Lubrication

All the four housing are totally enclosed. As such, do not require lubrication all through the year if properly fitted with quality grease. The silent blocks provided in the swing levers and small end housings should NEVER be greased or lubricated. Therefore, maintenance cost is Nil.

Technical Data

Power | 1 HP or 1.3 KW for the main machine |

| 1 HP for the Discharge Conveyor & 0.5 HP for the Feed Conveyor |

Floor Area | 3350 mm x 1505 mm |

Height | 2150 mm |

R.P.M | 270 |

Gross Wt. | 1805 kg. |

Net Wt. | 1660 kg. |